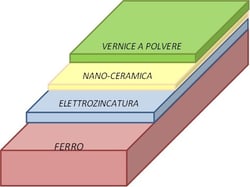

Unprotected steel degrades rapidly showing the formation of corrosion and/or rust. The SISTEMA PROMECH® allows maximum freedom of design ensuring corrosion protection combined with a

The SISTEMA PROMECH® allows you to:

- Protect steel against rust

- Safeguard the aesthetic and dimensional appearance of objects

- Safeguard threads and tolerances of a mechanical nature

- Achieve maximum aesthetic performance