POWDER COATING

POWDER COATING is a high aesthetic value anti-corrosive treatment that creates a smooth and homogeneous film on the surface of steel products, commonly known as iron and metal structural work.

Advantages

Speed of execution

POWDER PAINTING is quickly performed automatically and, upon completion, does not require additional drying time: the elements can be immediately packaged, shipped or assembled.

Certain timing in all weather conditions

POWDER COATING is performed on industrial plant systems that are not affected by weather conditions.

Solvent and VOC-free

The POWDER COATING process is solvent-free.

Even thickness

POWDER COATING allows you to achieve a film with an even thickness over the entire element, unlike the liquid coating which is directly proportional to the expertise of the operator and the application environment.

Architectural Paints

The paints used are designed to withstand atmospheric agents and UV rays, the main cause of fading colours. Cycles can be fine-tuned for special applications according to their intended use.

Guaranteed paint adherence

The secret of the paint adhesion lies in the pre-treatment. In the POWDER COATING system installations pre-treatments are constantly monitored and performed automatically. Something that can not easily take place in manual mode and on worksites.

INFO

POWDER-COATING allows you to:

- Protect steel against rust

- Preserve the structural characteristics of the metal elements

- Achieve maximum aesthetic performance

- Achieve the best possible inclusion of the work within the installation context by using the most appropriate colours

- Preserve the environment and non-renewable resources

POWDER COATING can be used in all environments: indoors, natural areas, urban areas and industrial areas. Special versions are designed for use in marine and off-shore environments or for heavy industrial uses.

Some of the most common elements treated are: gates, fences, railings, beams, roofing structures, storey buildings, pergolas, gazebos, as well as finished products such as lamp posts, litter bin posts and street furniture. View some application examples in the section Projects.

It is VOC-free (solvents) representing an excellent sustainable choice.

You can download the manual and other technical documentation in the download section.

Declaration of Conformity according to the UNI EN 10204 standard for every lot.

It is necessary to distinguish corrosion performance from aesthetic performance.

POWDER COATING can achieve a life expectancy of from 2 to 5 years, from 5 to 15 years and over 15 years according to the different environments in which it is used (indoors, natural, urban, industrial, marine). The paint film, intended as colour and gloss, has a life expectancy of from 10 to 25 years depending on the performance level required by the customer.

Ask our technicians for a customised application solution.

The POWDER COATING treatment developed by Nord Zinc has been specially formulated to guarantee the best possible results on hot-galvanized steel; however, the fact that it is a "Multimetal" cycle means it can also be used for coating raw steel and aluminium with excellent results.

The POWDER COATING treatment developed by Nord Zinc has been specially formulated to guarantee the best possible results on hot-galvanized steel; however, the fact that it is a "Multimetal" cycle means it can also be used for coating raw steel and aluminium with excellent results.

- MECHANICAL PREPARATION of the surface of the element by sanding with fine-grain abrasives, aimed at levelling off and uneven areas on the surface of the zinc coating.

- ALKALINE DEGREASING and surface etching, at a temperature of 50°C, to ensure contaminants such as oils and fats are removed.

- WASHINGwith mains water to remove residues of the previous treatment.

- DEMI RINSE, rinse using demineralised water.

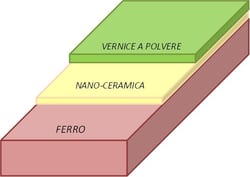

- SURFACE CONVERSION with a nano-ceramic process, a treatment that allows you to create a very stable and compact inorganic layer to guarantee high performance paint adhesion.

- DEMI RINSE,final rinse using demineralised water.

- DRYING in a hot air oven at a temperature of 140-150°C.

- POWDER APPLICATION: this phase foresees the actual application of the powder coating (in the required colour) by means of electro-deposition; it all takes place in an automated cabin with work station for any manual retouching required. There are many different types of powders used: epoxy, epoxy-polyesters and polyesters with the possibility of achieving smooth, textured and embossed finishes; all the powders used are "TGIC free" and specially developed for applications on hot-dip galvanized steel.

- POLYMERISATION (Firing): the powder deposition phase is followed by the curing phase in a hot air oven at a temperature of 180-200°C; the material remains in the oven for the time required for the powder to polymerise.

- REMOVAL AND CONTROL: removal of the materials from the transport equipment, followed by visual inspections to verify that there are no surface defects visible on the elements; the elements are now ready for the packaging phase.

- UNI EN ISO 12944 "Corrosion protection of steel structures by protective paint systems"

- UNI EN 13438 "Powder coatings for galvanized steel products used for construction purposes"

- UNI EN ISO 2409: Cross-cut test

- UNI ISO 9227: Salt fog test

- ISO 6270:Water condensation

- UNI EN ISO 1514: Standard panels for tests

.jpg)

.jpg)