What is it for

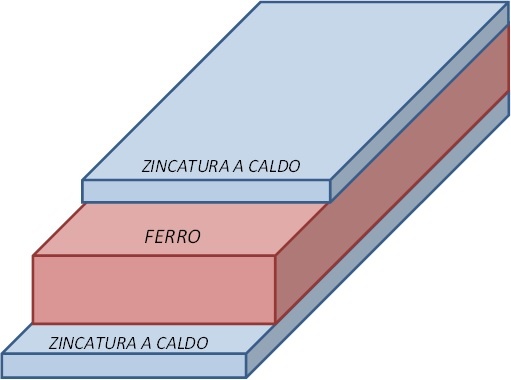

SIGILLO VERDE® hot dip galvanizing allows you to:

- Protect steel from rust, or what we commonly call iron

- Eliminate the typical maintenance against rust on metal products protected with paint

- Preserve the structural characteristics of the metal elements

- Safeguard the sturdiness of the weld seams

- Preserve the environment and non-renewable resources

- Declaration of Conformity according to the UNI EN 10204 standard for every lot

.jpg)