What is it for

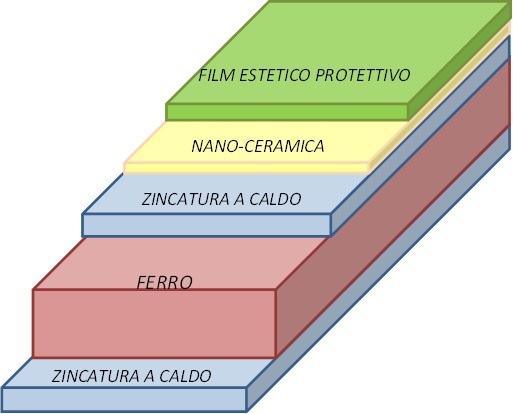

SIGILLO PLATINO hot-dip galvanizing allows you to:

- Preserve the shine and smart look of freshly performed hot-dip galvanizing

- Make the surface smooth and easier to clean

- Make the surface more pleasant to the touch

- Increase the life expectancy of the efficacy of corrosion protection

- …in addition to the typical advantages provided by SIGILLO VERDE®